PERFECT PACKING ASSOCIATES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PERFECT PACKING ASSOCIATES

Asbestos Gasket Sheet

Gaskets cut from sheet packing were used in a variety of industrial settings. Sheet packing was used in engine parts and other mechanical applications to resist the effects of steam, high pressure, water, oil and other chemicals. Chrysotile asbestos was traditionally used in the product, but in acidic environments some crocidolite was also used to prevent erosion. Gasket material and heat seals made from asbestos sheet packing were used in mechanical systems that involved the transport of gases, hot oils, steam, chemicals, grease or acid. Uses for these products include:

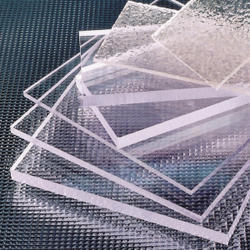

Product Description

Sheet packing was a common asbestos – containing product used to make gaskets for commercial and industrial settings. Asbestos fibers are mixed with a binding material and compressed to form the product, which can then be cut into various shapes and sizes to form gaskets and heat seals.

These products were used on pipes and boilers and in between joints on ships. When used in between pipe joints as a gasket, sheet packing prevents the contents of the pipe from leaking out.

Asbestos was commonly used as a component of this product because it provided resistance to high temperatures, as well as excellent durability and flexibility. Its cost effective nature also made asbestos an appealing material to produce gaskets and heat seals cheaply.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.